1. What Role Does the Engineer Vehicle U-Joint Play in Power Transmission?

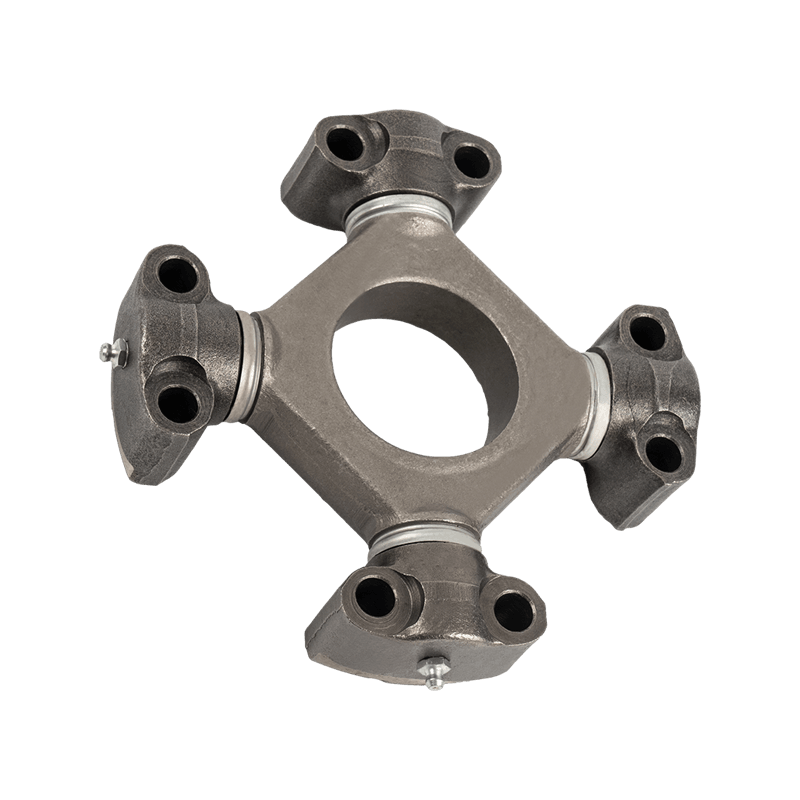

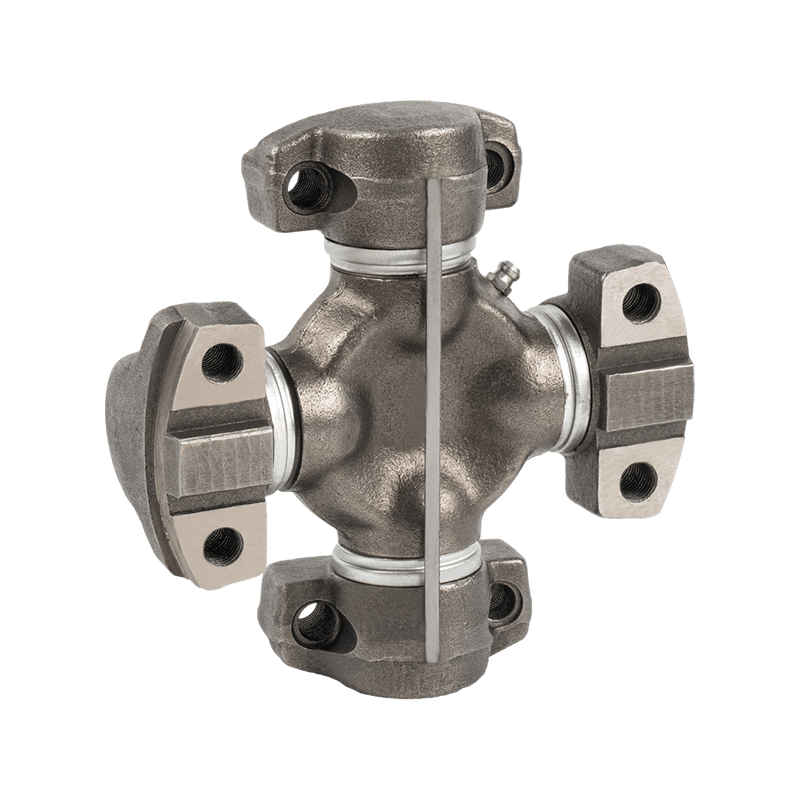

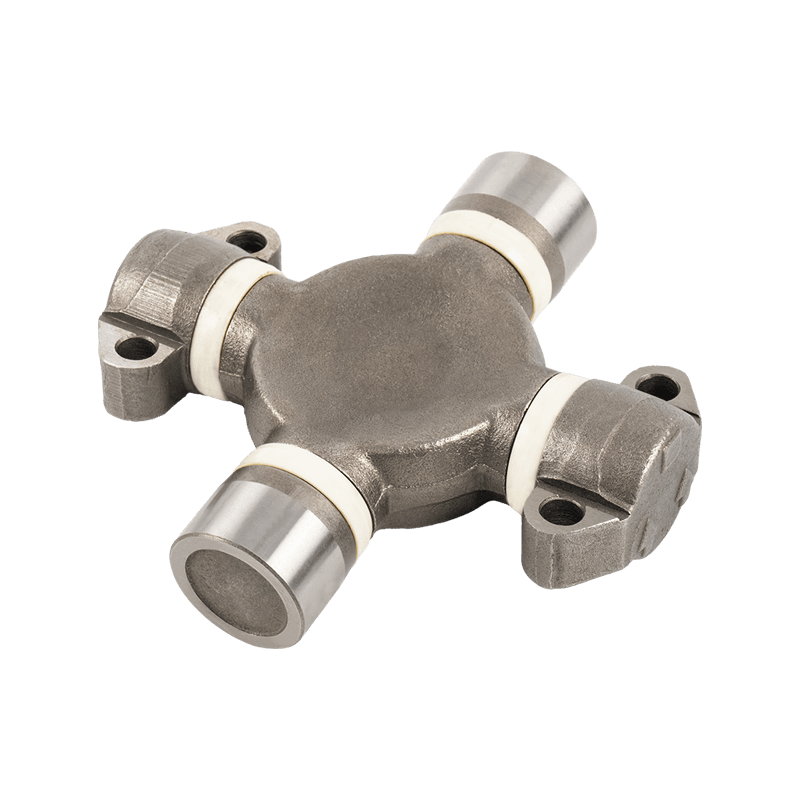

The Engineer Vehicle U-Joint is a fundamental component responsible for transferring torque between intersecting shafts within heavy-duty engineering vehicles. These vehicles encompass a wide range of applications, including bulldozers, excavators, cranes, and other construction machinery that rely on robust power transmission systems. At the heart of this transmission system lies the U-Joint, which accommodates the angular misalignment between shafts while transmitting rotational power efficiently.

In practical terms, engineer vehicles often operate in dynamic environments where flexibility and durability are paramount. U-Joints allow these machines to handle varying loads and movements, such as the articulation of hydraulic booms, rotational movements of digging arms, or the steering mechanisms of tracked vehicles. By facilitating smooth and continuous torque transfer, U-Joints contribute to the overall operational efficiency and maneuverability of engineer vehicles on construction sites.

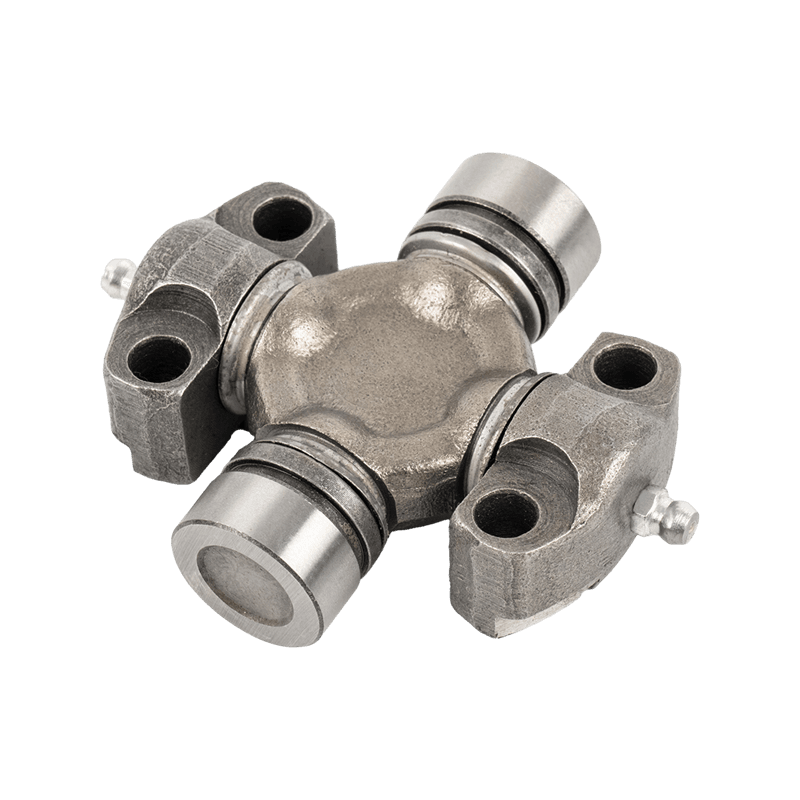

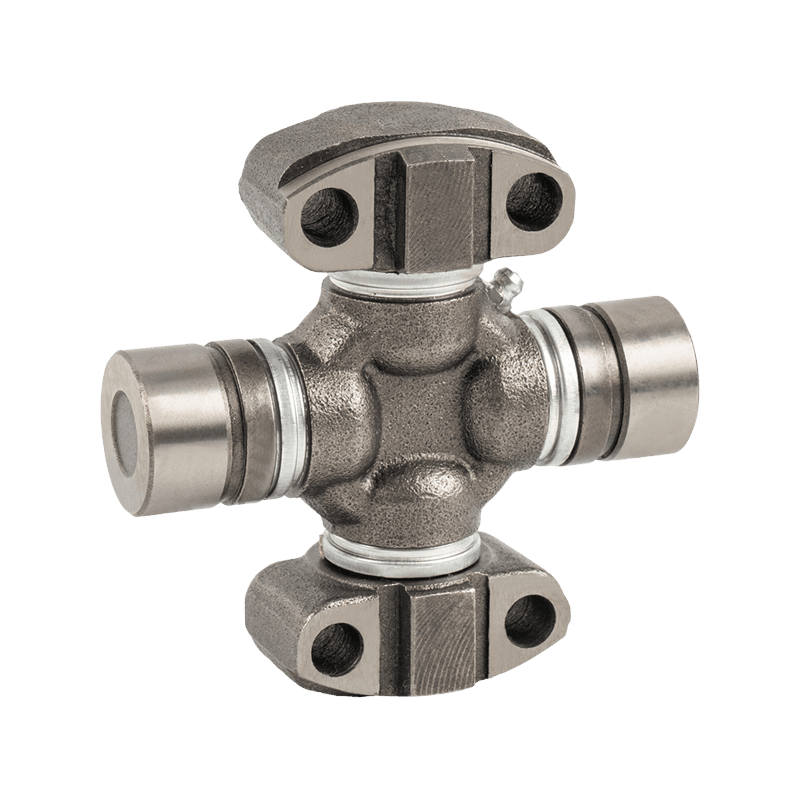

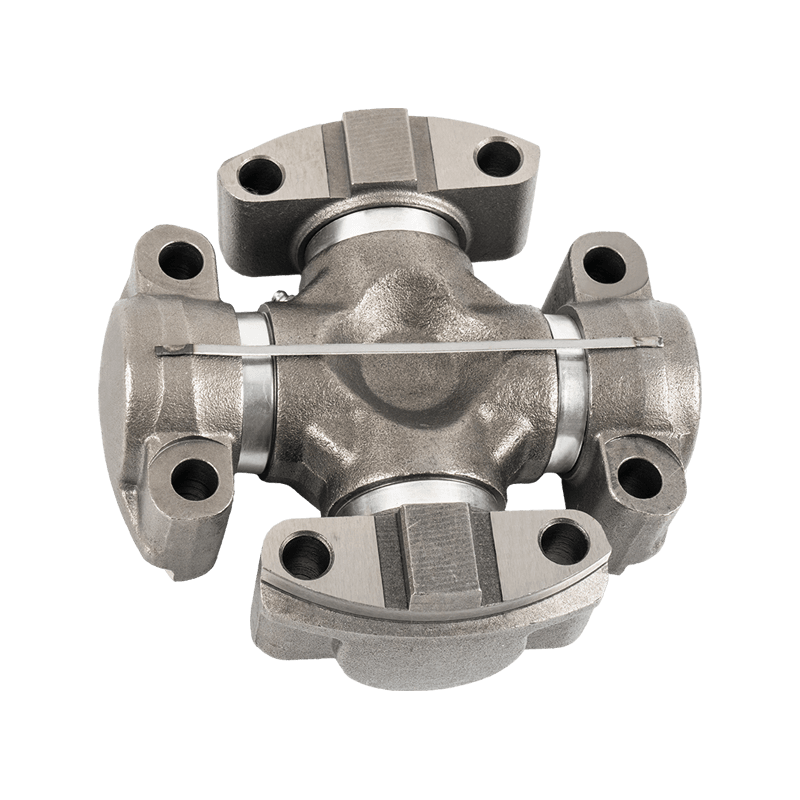

Engineer Vehicle U-Joints are meticulously engineered to withstand the rigorous demands of construction and earth-moving tasks. They are typically constructed from high-strength alloy steels or specialized alloys that offer superior durability and resistance to fatigue. The design incorporates precision machining and quality control measures to ensure precise fitment and alignment, minimizing wear and reducing energy losses during power transmission. This robust construction not only enhances the longevity of the U-Joint but also contributes to the reliability of the entire vehicle's drivetrain and hydraulic systems.

The efficiency of Engineer Vehicle U-Joints directly impacts operational costs and productivity on construction sites. By maintaining alignment and reducing frictional losses, these components optimize energy usage and contribute to fuel efficiency, which is a significant consideration in the heavy machinery sector. The ability to handle high torque loads without compromising performance makes Engineer Vehicle U-Joints indispensable for achieving consistent and reliable operation in challenging construction environments.

2. What Specialized Design Features Differentiate Engineer Vehicle U-Joints?

Engineer Vehicle U-Joints incorporate several specialized design features tailored specifically to meet the rigorous demands of heavy-duty construction environments. One of the primary distinguishing features is their enhanced sealing and lubrication systems. Construction sites are often characterized by harsh conditions such as dust, dirt, moisture, and abrasive materials, which pose significant challenges to mechanical components. To address these challenges, Engineer Vehicle U-Joints are equipped with advanced sealing mechanisms, such as triple-lip seals or labyrinth seals, designed to prevent contaminants from entering and damaging internal components. These seals effectively extend the service life of the U-Joint by protecting critical bearing surfaces and ensuring consistent performance in adverse conditions.

Some models of Engineer Vehicle U-Joints incorporate sealed lubrication systems or utilize self-lubricating materials. These innovations minimize the need for frequent maintenance interventions by providing long-lasting lubrication that withstands the demands of heavy-duty operation. By reducing downtime associated with lubrication tasks, these features contribute to improved operational efficiency and lower total cost of ownership for construction operators.

Another critical design consideration for Engineer Vehicle U-Joints is their high-torque capacity. Construction machinery often operates under extreme torque loads generated by powerful engines and hydraulic systems. Engineer Vehicle U-Joints are engineered with reinforced materials and precision machining techniques to withstand these forces without compromising performance or durability. This high-torque capability ensures reliable power transmission and operational stability during intensive tasks such as lifting heavy loads, digging through tough terrain, or maneuvering on uneven surfaces.

Engineer Vehicle U-Joints may incorporate design features aimed at enhancing serviceability and reliability in demanding environments. For instance, some models are designed with accessible grease fittings or inspection points that facilitate easy maintenance and routine inspections. These user-friendly features enable construction operators to perform preventive maintenance quickly and effectively, ensuring optimal performance and minimizing downtime on the job site.

3. How Can Proper Maintenance Practices Extend the Lifespan of Engineer Vehicle U-Joints?

Effective maintenance practices are essential for maximizing the lifespan and performance of Engineer Vehicle U-Joints in heavy-duty construction environments. Regular and proactive maintenance ensures that these critical components operate at peak efficiency, minimizing the risk of unexpected failures and costly downtime on construction sites.

One of the foundational maintenance tasks for Engineer Vehicle U-Joints is regular inspection. Routine inspections allow operators to detect early signs of wear, misalignment, or damage that could compromise the performance and safety of the U-Joint assembly. During inspections, it's crucial to check for abnormal noise, vibration, or play in the U-Joint, which may indicate potential issues requiring immediate attention or replacement of worn components.

Lubrication management is another critical aspect of U-Joint maintenance. Proper lubrication reduces friction and wear between moving components, thereby extending the service life of the U-Joint and ensuring smooth operation. Manufacturers typically provide specific guidelines regarding lubrication intervals and recommended lubricants based on operating conditions and environmental factors. It's essential for operators to follow these recommendations to maintain optimal performance and prevent premature wear or failure of U-Joints in engineer vehicles.

Protecting Engineer Vehicle U-Joints from environmental factors is essential for prolonging their service life in harsh construction environments. Construction sites expose equipment to dust, dirt, moisture, and abrasive materials, which can accelerate wear and corrosion of U-Joint components. Implementing protective measures, such as installing shields or covers around U-Joints, helps minimize exposure to contaminants and preserves the integrity of critical components over time.

In addition to regular inspections and lubrication management, proactive maintenance practices include timely replacement of U-Joints when wear or damage exceeds acceptable limits. Using genuine replacement parts recommended by the equipment manufacturer ensures compatibility and maintains the reliability of the U-Joint assembly. Scheduled replacement intervals may vary depending on the application and operating conditions, so operators should adhere to manufacturer guidelines to maximize the longevity and performance of Engineer Vehicle U-Joints.